|

|

|

| |

|

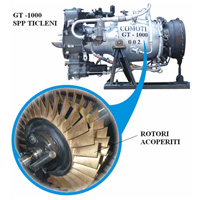

3.4.2 MATNANTECH - New materials and technologies for coating turbine |

|

|

Contract 110/ 2002 - finalized - MATNANTECH Program

NEW MATERIALS AND TECHNOLOGIES FOR COATING TURBINE ROTORS

|

PARTNERS:

INCDT COMOTI Bucharest

INOE 2000 Bucharest

SC PETROSERVICE SA |

Project’s objective is accomplishing „ TURMO IV C turbine motors of NCK 18TDA material coated with multi-layer structure Ti/TiN/TiAlN/Al2O3”. By applying, according to a new technology, a multi-layer structure on turbine disc’s blades equipping the gas generator of the TURMO IV C engine, high capabilities rotors are obtained.

Increase of rotor life spam as a result of oxidation resistant layers coating will generate:

· decrease of rotor’s cost / functioning hour;

· decrease of rotor using installations service costs;

· decrease of losses generated by TURMO IV C industrial engine functioning stoppage due to service operations.

Project placing:

Ţicleni Unit – TURMO IVC engine gas generator

Usage areas:

· Methane gas extraction and distribution installations, using turbine engines with vital spare parts made and maintained by INCDT COMOTI

· Oil extraction and distribution installations, using superchargers produced or maintained by INCDT COMOTI

Domains:

· Industrial applications

· Aeronautics

Project’s result:

· Obtaining a special material (with multi-layer structure Ti/TiN/TiAlN/Al2O3) intended for coating NCK18TDA super alloy turbine blades for increasing usage time with at least 30% (in TURMO IV C – industrial engine’s gas generator functioning parameters)

· Accomplishing new, up-to-date technology, for coating NCK18TDA super alloy turbine rotor blades

|

|

|

|

|

|

|

|

|

|

| |

| |

| 3.13. HeliAc PN III, Program 2 |

|

|

| 3.14. Programul PN III PED |

|

|

| 3.14. Programul PN III PED |

|

|

|

|

|

|