Contract 120/2003 – finalized - INVENT Program

DIAGNOSIS INSTALLATION AND TECHNOLOGY FOR DEFECTS OF HIGH ROTATION SLIDING BEARINGS WITHIN REVOLVING MACHINES

|

PARTNERS:

INCDT COMOTI Bucharest

SC PETROSERVICE SA |

Project’s goal: is making Bearing’s diagnosis installation and a testing-diagnosis-certification technology (method) for high rotation sliding bearings within revolving machines, for the first time in our country.

Relevant domain for this project is “high end ”, revolving machines being used more and more in any country’s economy. Bearings are vital components of revolving machines; higher performance for the bearings results in higher input for the machines.

The project has instant usage within revolving machines (compressors, turbines, blowers), which, besides being very widespread, are more and more in the attention of national economy. Approaching such a project, show the interest of Romanian specialists to grasp new domains, belonging until today to high industrialized countries, domains in which, our country’s economy was totally dependent of most economical powerful state’s technology.

Approached area, accomplishing an prototype installation and testing-diagnosis technology (method) for high rotation sliding bearings, it’s one of the advanced techniques for promoting technological transfer and innovation aimed at increasing Romanian economy competitiveness. Through it’s results, this project will decrease supplied bearing costs and increase productivity ( “more bearings passing certifications” by cheap and viable solutions for maintaining revolving machines using the bearings in functioning capability as soon as demands appear).

In the same time, we must mention the clear politics of current government, which foreseen focusing every effort for integrating the Romanian economy in Euro-Atlantics Economical Structures (in our case namely to provide a testing-diagnosis technology (method) for high speed sliding bearings in order to assure bearing supplier to be at the same level, is not superior, as far as quality is concerned, to western manufacturers).

Final goal of this project is “to create technical and material foundations in order to produce competitive bearings”, in order to allow for Romanian producers access to western markets at a high scientific level.

There were made, tested and certified as well a product (installation-bench) and a technology (method), both innovative and premiers in our country

Project placement: Bearings diagnosis installation is at INCDT COMOTI Bucharest

Project result:

· Developing a new testing-diagnosis-certification technology for high speed sliding bearings for revolving machines;

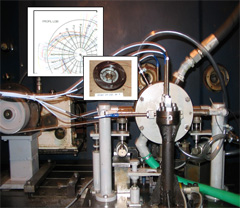

· Designing and manufacturing of a ”Defect diagnosis installation (bench) for high speed sliding bearings”. The installation allows static functioning characteristics determination (ex. lifting power, friction moment, lubricant layer minimum thickness, oil flow), which is another objective of this project, absolute premiere for our country;

· Issuing a complex diagram for possible fluctuations of the bearing’s geometrical profile in order to assure functioning working parameters.

· The results obtained with diagnosis technology and installation for high speed sliding bearings used by revolving machines reach new national levels for technical and technological objectives minimizing all required expenditures. According to calculations, new technology costs are recovered (even with a 10% profit) by reducing rejects rate by at least 25%.

· Technical parameters determined with the diagnosis installation are those of the high speed sliding bearings used by high performance revolving machines, this meaning that the solved problem’s will maintain for the entire exploitation period of the installation ( 7 - 10 years).

· Diagnosis installation for high speed sliding bearings allows development of new technological studies regarding non-friction materials, behavior of various liquid lubricants.

|