| Stage I

During the first stage of the project were to conduct research related to emissions reduction methods and increase efficiency in cogeneration plants and turbochargers for compressing natural gas from INCDT COMOTI achievements in the field.

Projects INCDT COMOTI: GTE-2000 Botosani cogeneration plant (left) and 2xST 18 - Suplacu de Barcau (right)

These achievements of INCDT COMOTI are regarded as potential locations for checking integrated technology will be developed in the project. Technical-scientific results of stage have resulted in: a study of solutions in principle = 1 pc.; design concept for integrated technology = 1 pc.

Stage II

During stage II of the project were developed mainly for research activities related to numerical modeling of processes in afterburning system and afterburning project.

Burning module for afterburning from cogeneration plant 2xST 18 - Suplacu de Barcau, temperature variations along the axis at ST18 module (left) and ST18-module R (right), on natural gas and burning gases from turbo engine

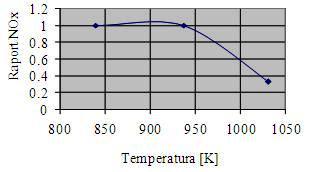

The variation of the NO x ratio between ST18-R and ST18 modules with hot gases temperature

Technical-scientific results of stage is focused on: preliminary numerical model = 1 pc; technical project = 1 pc, theme design technology = 1 pc, disseminating researches results = 3 scientific papers.

Stage III

At this stage of the project were developed mainly research activities related to obtaining experimental data on integrated technology to a potential customer, documentation on burning gaseous fuels, a database with potential users of the technology developed.

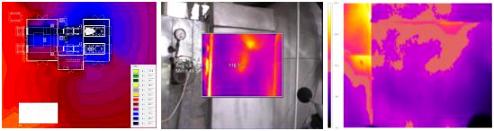

Mobile laboratory COMOTI and analyzer gas PG 250 Horiba with the measurement probe in a stack at the heat recovery steam generator

Experimental data related to chart of noise and infrared images to cogeneration power plant 2xST 18 - Suplacu of Barcau

Participation of young researchers in the project 21-056/2007 (numerical modeling, measurements, data processing and analysis of results, dissemination of results)

Technical-scientific results of stage is focused on: a set of experimental data complex and schemes = 1 pc, documentations = 2 pcs, database = 1 pc, disseminating researches results = 3 scientific papers (two papers ISI).

Stage IV

Starting from the burner of cogeneration plant 2xST 18 were held, mainly, researches related to execution of the afterburning, laboratory model, and documentation for test.

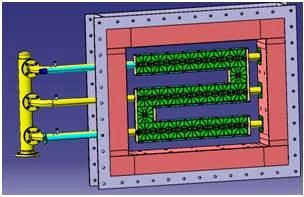

The afterburning, 3D model, from the cogeneration plant 2xST 18 - Suplacu of Barcau

Afterburning INCDT APC 1MGN, in laboratory model variant

INCDT COMOTI stand for testing of combustion chambers and other components of turbo-engine

Technical-scientific results of stage IV consist on: afterburning burner for testing in laboratory (2 variants); technology by laboratory for extended combustion module = 1 pc; documentation experimentation = 2 pcs, stand design theme for trying afterburning modules = 1 pc; researches thematic for an application for invention = 1 pc; disseminating researches results = 2 scientific papers (one paper ISI).

Stage V

In the stage V were developed mainly for research activities related to experiments on fuel flow control system / air from 2xST 18 cogeneration power plant - Suplacu de Barcau, manufacturing automation cabinet stand, experiments on bench for an afterburner with one module, advanced model numerically, integrated technology development efficiency - reducing emissions, in the laboratory, preparing and filing patent documentation.

Execution of the afterburner with one module, tested at University Politehnica of Bucharest (UPB), Classic and Nuclear Thermo-mechanic Equipment Department

Isotherms at recording infrared for afterburner with one module, testing on bench at UPB with different air flow rates of natural gas (from left to right, Qcomb. = 0.5 to 0.88 m 3 / h)

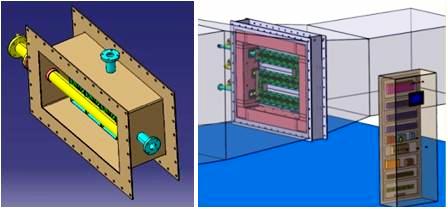

Automation cabinet for the testing bench on afterburning

3D design of extend solution for afterburning installation - in laboratory variant (left) and 3D design automation cabinet for afterburning installation in industrial variant (right)

Technical and scientific results of the stage V is materialized: experimental data on fuel flow control system / air from 2xST 18 cogeneration power plant - Suplacu de Barcau (one set), automation cabinet for the testing bench (1 pc), experimental data on the afterburner with one module (1 set), improved numerical model (1 pc), laboratory technology (1 pc), patent documentation (1 pc), updated website (1 pc), one ISI paper.

|