| Project Results

According to the project’s aims was realized the coolant purification installation which is an advanced system that has the capacity to process dirty cooling fluid, contaminated and used, in order to purify it by replacing the used inhibitors and to return it for being reutilized.

The coolant purification system starts the technological process by pumping the used coolant through the working unit. The final phase consists of simply adding the necessary ethylene glycol, the antifreeze or the water, necessary in order to reach the desired protection level against frost; then, it is added the necessary quantity of inhibitor and pH adjustor.

The elaboration and qualification of the new technology for recovering dangerous chemical substances from the used coolants was based on the following criteria:

- The criterion of technical feasibility – the technology has to correspond to the proposed objective and to be reproducible, having in view the elimination of the risk factors anticipated or identified during the experiments, which could compromise the process;

- The criterion of economic feasibility – the following conditions have to be met:

- capacity of coolant purification per time unit sufficient so that the procedure is profitable;

- convenient costs for maintenance and exploitation.

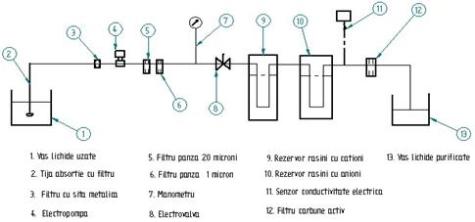

Fig.1 The scheme of the purification installation

During the development of the project, technological solutions to separate and recover dangerous chemical substances form the used coolants have been studied and experimented. Based on the acquired knowledge and experience, it has been elaborated the technological scheme of the experimental model, it has been realized the experimental model of the PEM purification installation, as well as the tests for the system’s verification and qualification.

We consider that we have managed to obtain a perfectly viable system that we were able to realize practically and that allows a possible improvement or adaptation to specific working conditions. By means of experimental activities, there were realized a range of tests, according to the technology selected in the project. It was aimed that all the materials used at the realization of the installation and those also that interfere in the technological process, to be accessible, easy to provide from the intern market, but having a maximum efficacy within the technological process.

|