Project Events

July27 - July29 2008 - Conference “Excellence Research – the way to Innovation”

“THE NEW APPROACH OF THE MAINTENANCE. THE ANALYZE OF THE MONITORING, CONTROL AND CHECK UP PROCESSES FOR THE FUNCTIONALITY OF THE TURBOJETS”

Project Results

Maintenance technology. Monitoring technics and maintenance applied to a turbine that belongs to the cogenerative power station Suplacu de Barcau.

The new maintenance technology includes all the works that are beeing done to secure a normal operation, in the parameters impose by the power stationís working regims.

Exploitation before the diagnosis |

- long operational periods |

Management of the information /results check |

Calculation procedures for the remained resource |

- start up numbers |

- functioning malfunctions |

- normal operation |

Engine’s performance |

- engine’s parameters |

Calculation procedures and comparisons |

- atmospheric conditions |

Functioning parameters |

- evolutions in time |

Comparison |

Transitional regimes |

- the diagram of evolution |

Settings |

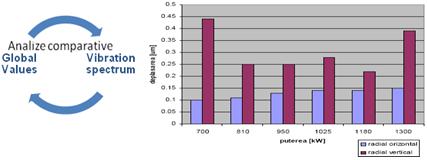

Engine’s vibrations |

- Global values |

Comparative analysis |

- Vibration spectrum |

Oil’s quality |

- metallic residues |

Correlations and interpretations |

- chemical analysis |

Engine’s systems |

- parts wear |

Procedură de calcul a resursei, setări

Calculation procedure for the resource, settings |

- level of tolerance |

- gears resource |

- functionality |

Air intake |

- pumping limits |

Comparisons |

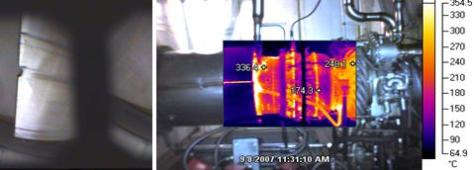

Interior integrity |

- videoscope inspections |

Correlations and interpretations |

- radiographies |

- feedback (response control) |

Internal tolerance |

- direct measurements |

Comparisons |

- the use of specific instruments |

Local overheating |

- infrared inspection |

Correlations and interpretations |

- oil cooling in bearings |

- Temperature’s field of the burnt gases |

Quality of the combustion gases |

- Injections checking |

Correlations and interpretations |

- chemical composition of the burnt gases |

Overall integrity of the engine |

- visual check for the exterior |

Interpretations for analysis |

- manual spinning |

- noise level and spectrum |

The “tools box” of the predictive maintenance

- Computers of great performance

- Dynamic ballancing machine for rotary assembly

- Videoscop inspection for the interior of the engines – borosco camera

- Dispozitive pentru masuratori tridimensionale

- Equipment for 3D measurements

- High performance equipment for measuring the noise and vibrations

- High tech equipment for the analyze of the quality and chemical composition of the air

- Infrared camera

Function parameters. Function monitor for the engine

Measurements and vibration analysis

Boroscop inspection; Infrared inspection

INCDT COMOTI, through its scientifical and technological activity introduce new and modern methods to ensure a predictive maintenance according to the european standards and directives.

Institute’s politics, regarding this sector of activity, is to continuously develope the endowment of its scientifical laboratories with equipment and gear needed for complex maintenance works; to introduce new methods, technics and modern technologies to realize these works, and to widen the range of the services done at the highest level, according to european directives and national legislation, suporting in this way the industrial manufactureres in their search to diminish the maintenance costs and to protect the environment.

Potential users are: PETROM , TRANSGAZ, ROMGAZ, etc.

|