|

|

|

| |

|

2.20 TIDE |

|

|

DETAILED DESCRIPTION

Project summary

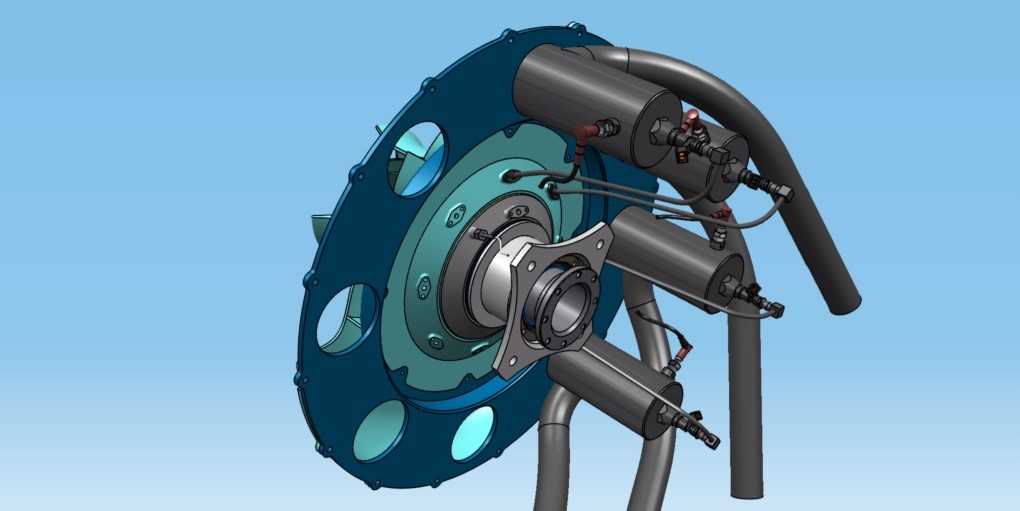

The project proposes the investigation of an innovative technology regarding propulsion systems, technology that could trigger a radical change in air transport in the second half of this century. The proposed solution by this project is the replacement of the aviation engine's classic turbine with a simpler system, but at least as efficient. The proposed concept, called TIDE, uses the conservation of the tangential momentum generated by the exhaust gases to rotate the entire assembly of the combustion chamber. The combustion chamber assembly shaft is connected, and provides the necessary power, to an upstream compressor which delivers the pressure needed inside the combustion chamber assembly housing. The remaining energy will be used to power up the aircraft. The project aims also to address another radical idea, namely using supersonic combustion. This will lead to a more efficient propulsion in the case of super and hypersonic flights. The solution presented in the project, to achieve supersonic combustion, is the pulsed detonation combustion chamber (PDC).

|

|

Project Objectives

The main goal of the project is to prove the functionality and feasibility of the concept, opening the road towards developing a mature technology over the next 50 years.

Specific objectives:

1.The design and numerical simulation of the engine compressor, adapted to the requirements of the new engine;

2. The constant volume cycle is of higher efficiency than the classical Brayton cycle. Due to the elimination of the classical engine turbine, the maximum temperature limitation will be removed, thus allowing an overall increase in the engine performance and efficiency. The project aims at demonstrating the increase in theoretical cycle efficiency;

3. Provide a full definition of the engine constructive solution;

4. Provide a numerical simulation of the flow through the engine that will allow the estimation of the engine performances;

Estimated results

-

The most important result expected from the proposed project is to demonstrate, both numerically and experimentally, that the power provided by the rotating PDCs can provide the energy to accelerate the compressor to the speed required for its design performance, with sufficient excess energy to power up the aircraft;

Practical realization of a high frequency, self-supporting ignition PDC; The project will provide an integrated solution for the proposed concept, validated through numerical simulation, and laying the foundation for building a demonstrator engine concept in the future; Main activities

-

Project management and coordination

-

Ensure the visibility the project

Participation in the development of geometry and constructive solution of the compressor, combustion chamber and engine assembly Define operating parameters and performance that is expected to be develop by this engine Numeric case definition and coordination of numerical simulations Deliver the design solution for the fuel injection and ignition systems, integrate the results in a geometric model of demonstrator, deliver technical drawings of the fuel injection and ignition systems components, coordinate the design of the testing rig adjusting components Provide design solutions for bearings and cooling and lubrication systems

Manufacturing the demonstrator, fuel injection and ignition systems and the testing rig adjusting components Instrumentation and calibration of the testing rig Installing and testing the concept

|

|

|

|

|

|

|