|

|

| |

|

COMBUSTION CHAMBERS AND UNCONVENTIONAL ENERGIES LABORATORY |

|

| |

|

|

|

|

MAIN

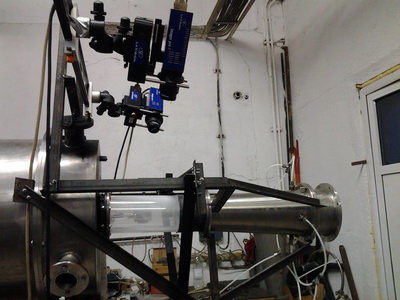

FACILITIES, TESTING AND EXPERIMENTAL LINES

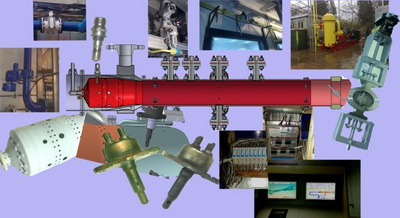

General Diagram

| Air Sources |

Fuel Sources |

1. Flow Rate: max. 10

kg/s

Pressure: max. 1,14 bar

Temperature: atmosferic |

1.

Kerosen, Diesel

Flow Rate: max. 0,5 kg/s

Pressure: max. 90 bar |

2. Flow Rate: max. 10

kg/s

Pressure: max. 1,14 bar

Temperature: max. 600 K

(mixing pre-heater) |

2.

Natural Gas

Flow Rate: max. 3000 Nm3/h

Pressure: max. 15 bar |

3. Flow Rate: max. 8 kg/s

Pressure: max. 16 bar

Temperature: max. 800 K

(humidity control pre-heater) |

3.

Gasification, biomass, wood materials

|

4. Biofuels

(camelina, ecodiesel, etc.) |

Main Experimental Lines:

- R.1 - High Pressure Line (max air:14 bar; 6 kg/s; t 200 C;

burned gases temperature max 1600C)

- R.2 - Low Pressure Line (max air 1.12 bar; 4 kg/s ; atmospheric temperature)

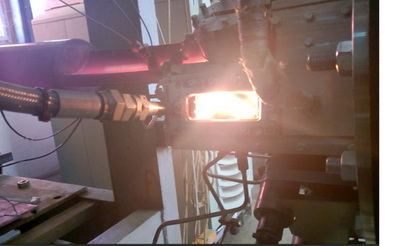

- R.3 - High Pressure Line with optical acces (air max:14 bar-0.5 kg/s, t 600 C; electrical pre-heater)

- R.4 - High Pressure Line with optical acces (air max:6 bar-1.0 kg/s, t 2500 C; gas burner pre-heater)

- R.5 - Experiemental Line - Burners for biomass, gasification (200 KW)

|

|

Maximum Capacity

|

Instrumentation

|

|

Air flowrate

|

Air pressure,

absolute

|

Inlet air temperature

|

Natural gas

|

Liquid fuels (Kerosen, Diesel, other)

|

|

C 1

|

6 kg/s

|

1600 kPA

|

atmospheric

|

0.23 kg/s

|

0.27 kg/s

|

Optically-Accessible Pressure sensors,

thermocouples, strain gauges, noise, flow

meters, Emission analyzers

|

|

C 2

|

2 kg/s

|

1600 kPA

|

773 K

|

0.07 kg/s

|

0.08 kg/s

|

Optically-Accessible Pressure sensors,

thermocouples, strain gauges, noise, flow

meters, Emission analyzers, air-gas air

heather

|

|

C 3

|

0.5 kg/s

|

1600 kPA

|

1073 K

|

0.02 kg/s

|

0.02 kg/s

|

Optically-Accessible Pressure sensors,

thermocouples, strain gauges, noise, flow

meters, Emission analyzers, electric air

heather

|

Main Instrumentation and Facilities:

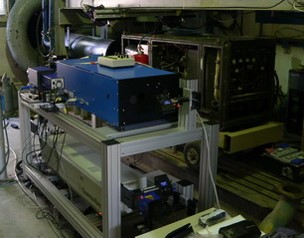

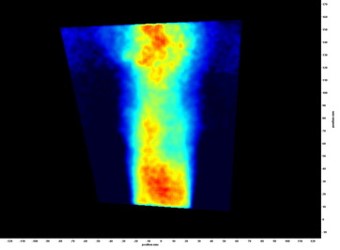

- PIV (Particle Image Velocimetry) LaVision - nonintrusive measurment line

- LIF (Laser Induced Fluorescence) LaVision - nonintrusive measurment line

- SIKC-MAIHAK ultrasonic flowmeter for gaseous measurments (0.5% precision)

- Flow measurments with diaphragm and Venturi tube

- KIMO Pitot tube(1 %, for a ± 10 ° alignment,ap to 1000 °C)

- MRU VARIO Plus - portable burned gases analizer (CnHn,CO,CO2, NOx,H2)

- IMR2000 - burned gases analizer (O2/CO/NO/CO2/CxHy)

- Micro turbine engine Garret GTP 30-67 (25 KW)

- Micro turbine engine Capstone C30 (30 KW)

- 72 CPUs Core Intel XEON Supercomputer - for CFD analysis

- Automatic Multifuel Oil Burner - model KG/UB 100

- Laser Pirometer - laser LaVision

- Control valves for high pressure and temperature

- Electrical valves for air flow control, for liquid and gaseous fueles flow control

- PLC data aquisition system (0.15s/1 K program)

Software:

- ANSYS: CFX, Fluent

- CATIA

- SOLIDWORKS

- SOLIDEDGE

|

| |

|

|