SUPERCHARGER SET FOR NATURAL GAS

|

NATURAL GAS COMPRESSION INSTALLATION EQUIPPED WITH SUPERCHARGER SET GTC-1000

ŢICLENI UNIT– PETROM SA, TG. JIU BRANCH |

Usage areas:

· Compression of methane gas at natural gas extraction units;

· Compression of crude oil associated gas at crude oil extraction units;

· Rising gas pressure in medium or high pressure pipelines within gas transportation and distribution units.

Use:

At the moment, there is a supercharger set GTC-1000 within Ţicleni Unit - Tg. Jiu, that compresses natural gas obtained by extracting crude oil from oil fields in order to deliver it to de-gas installations and/or to high pressure compression installations for gas lift process, used within extraction units or to be delivered in main pipelines.

|

SUPERCHARGER FOR NATURAL GAS

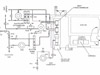

GAS COMPRESSION INSTALLATION DIAGRAM WITH GTC-1000 |

| VAG |

- general anti-pumping valve; |

VAJ |

- low pressure compressor anti-pumping valve; |

RAG |

- gas admission valve; |

REM |

- main pipeline exit valve; |

RP |

- pressuring valve; |

RI |

- main aspiration pipeline insulating valve; |

RE |

- main heading pipeline insulating valve; |

REC |

-- exhaust to chimney valve; |

R1; R2 |

- combustion gas closing valve; |

RPGC |

- combustion gas adjustment valve; |

SGA, SGR, SGC, SGI – fluid fractions separator. |

|

SUPERCHARGER FOR NATURAL GAS

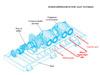

SUPERCHARGER SET GTC 1000 CONFIGURATION |

Product components

The supercharger set is composed out of the next building blocks:

· Air aspiration cell with filter cartridges of 25-50µm filtration capacity;

· Supercharger set cell;

· Noise dumper;

· Power set;

· Coupling;

· Gas compression system made out of two intermediate cooling compressors in sequence;

· Oil system including:

o Lubrication oil system;

o Dam oil system;

o Tightening gas system.

· Gas combustion and starting system;

o Fire proof installation;

o Automation installation with following functions:

o Automatic powering up and down of the set;

o Adjustment of functioning regime of the set maintaining it within proper parameters;

o Set protection in case of exceeding normal parameters values;

o Adjusting gas compressors through anti-pumping system;

o Displaying main oversight parameters of the set.

· Data acquisition system that follows on computer the technological process throughout entire compression unit.

Main characteristics

| Environment conditions |

|

- Environment |

Continental moderate |

|

- Temperature |

-30÷40 |

oC |

- Altitude |

0÷1000 |

m |

| Main parameters (ISO conditions) |

|

| - Nominal power |

690 |

kW |

| - Aspirated gas pressure |

1,5÷1,8 |

bar abs. |

| - Aspirated gas temperature |

0÷50 |

oC |

| - Headed gas pressure |

7,0÷7,5 |

bar abs. |

| - Headed gas temperature – max. |

130 |

oC |

| - Pumped gas flow |

185.000 |

Nmc/day |

| - Combustion gas consumption |

7.800 |

Nmc/day |

| - Power group oil consumption – max. |

0,5 |

liters/day |

| - Compressors oil consumption – max. |

5 |

liters/day |

| - Maximum external sizes |

8.100 x 3.700 x 3.620 |

|

| - Total set weight |

19.000 |

kg |

The compression of natural gas is made with intermediate cooling, between compressors, witch leads to a substantial decrease in power consumption during the process.

Optional

Supercharger set can be used with an recovery boiler, placed on burning gases exhaust, in co-generative configuration, in order to produce industrial steam or heated water, saving huge amounts of energy.

In that configuration, ISO conditions are:

Mechanical power on axle |

690 |

Kw |

Burning exhausted gases temperature |

505 |

oC |

Burning gases flow |

5,2 |

kg/s |

Fuel consumption |

0,090 |

Nmc/s |

Total energy injected into the group (for PC of 36.830 KJ/Nmc) |

3.344 |

kWh/h |

Supplied saturated steam flow |

2,7 |

t/h |

Gross thermal efficiency |

85,5 |

% |

|

|

| POWER GROUP WITH FREE TURBINE |

NATURAL GAS COMPRESSORS |

|

|

|

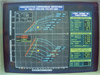

| AUTOMATIC SWITCHBOARD FOR THE GROUP |

GROUP COMPUTER FOLLOWING |

|

Obtained results

The group has been installed in 1993 and it pumped until now over 500 millions Nmc of gas, summing over 65.000 functioning hours, reassuring at that time the unit’s pumping capacity and in the same time bringing all of the important advantages of using pumping groups, making use of gas turbine motors as power source and the centrifugal compression compressors as an equipment.

Benefits for using the GTC-1000 supercharger set:

· Package (skid) type construction, reduced in weight and sizes;

· High level of automatic and of electrical energy autonomy;

· Functional characteristics allow a high degree of flexibility and adaptation on working parameters variation (compressed gases entry/exit pressures);

· Reduced oil consumption;

· Possibility of placement in the open, without being needed a protective structure;

· Large resource between overhauling and maintenance interventions;

· High average availability yearly usage percentage (functioning time/real time) – 86%;

· Low exploitation and maintenance cost due to low personal requirements and low price of spare parts compared to the resources between interventions;

· Optional, a heat recovery boiler can be placed on the exhaust of the combustion gases for production of industrial steam or hot water, considerably improving the thermal efficiency of the installation.

INCDT COMOTI offers it’s services through highly trained personnel for on time and high quality of revision and repair interventions according to the schedule specified in the exploitation and maintenance specifications, as well as unscheduled interventions in excellent conditions for the beneficiary, insuring installation’ s maintenance and usage in appropriate conditions.

UPGRADING THE GTC-1000 SUPERCHARGER SET:

The possibility of upgrading the GTC-1000 supercharger set through equipping it with an type ST18 Pratt&Whitney turbine engine with greatly improved performance is analyzed at the moment. By this upgrade, the supercharger set performance is radically improved.

The developed set general characteristics are as follows:

| Environment conditions |

|

- Environment |

continental moderate |

|

- Temperature |

-30÷40 |

oC |

- Altitude |

0÷1000 |

m |

| Main parameters (ISO conditions) |

|

| - Nominal power |

1.450 |

kW |

| - Aspirated gas pressure |

1,5 ÷1,8 |

bar abs. |

| - Aspirated gas temperature |

0 ÷50 |

oC |

| - Headed gas pressure |

10 ÷12 |

bar abs. |

| - Headed gas temperature – max. |

130 |

oC |

| - Pumped gas flow |

300.000 |

Nmc/day |

| - Combustion gas consumption |

14.500 |

Nmc/day |

| - Power group oil consumption – max. |

1,2 |

liters/day |

| - Compressors oil consumption – max. |

5 |

liters/day |

| - Maximum external sizes |

8.100 x 3.700 x 3.620 |

|

| - Total set weight |

19.000 |

kg |

|