The tests demonstrate the good operation of the turbo transmission, with the operating parameters within the prescribed limits. There have been realized a planetary gearbox and a HS coupling, with high level performances, international competitive, showed below.

Prime mover/ Driven machine |

Gas Turbine/ Electric Generator |

Rated power |

2000 kW |

Maximum overload torque |

5 x full load (Transient Condition) |

Input speed (nominal requested) |

19,000 rpm |

Exact input speed at requested output |

18,965 rpm |

Momentary Overspeed |

23,800 rpm |

Output speed |

1,500 rpm |

Duty cycle |

Continuous |

Gearbox life, Bearing life |

> 30 years |

| Gearbox noise |

88 dBA @ 1 m |

Efficiency @ 100 % load |

>98.0 % |

Instrumentation |

|

RTD type |

PT 100, 3 wire |

Low speed journal bearing |

1 Duplex Rigid Head RTD |

High speed journal bearing |

2 off RTD’s |

Speed probes |

2 Airpax (or equivalent), located on high speed case |

Vibration detectors |

Provision for vibration sensors as detailed on drawing |

Vibration Level |

Alarm 4mm/sec rms, Trip 5mm/sec rms |

Economic considerations on the project

The major transmission components are expensive and have a significant amount in co-generative plant costs. Reducing transmission costs is an important objective achieved by the project. The initial assessment of the possibility to reduce the major components cost by 25-40% compared to imported ones, has been confirmed. A high performance 2MW gearbox was realized with costs of 60-65% of the equivalent gearbox supplied by Allen Gears (Rolls Royce Group, in operation at cogeneration plant 2xST18 Suplacu de Barcău).

Reducing of the transmission costs was allowed by the integration of the gearbox design and manufacture in the COMOTI - RENK Resiţa partnership. The realization capacity of the gearbox is ensured by C OMOTI (concep t ion, design, rotors balance, instrumentation) and RENK Reşiţa (manufacturing), and for HS coupling by COMOTI.

The 2 MW power transmission, as designed in the project, is integrated to the cogeneration plants offered by COMOTI.

From scientific point of view, the project allowed the consolidation of a stable partnership. At present, INCDT COMOTI has new or in course of realization research projects, with all the partners of this project. It is to be relieved the involving in R&D activity of an important gears manufacturer such as Reşiţa REDUCTOARE S.A. (Reşiţa RENK). On a national point of view, the high performance power transmission realisation, including planetary gearboxes and HS couplings, represents an obvious technical progress. Implementation of them in the future cogeneration plants, will lead to reducing costs of the energy production. From social point of view, this will lead to the involving and education of high qualified personnel, both for fabrication of the transmission and for the operation and maintenance at the cogeneration plant beneficiary.

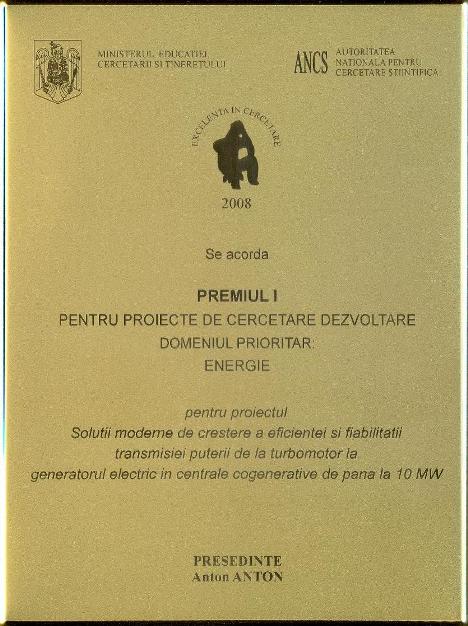

AWARD 1 for research projects in priority development of energy:

|