|

| |

|

Partitipation at National Programmes |

|

|

| 3.11.3. ADCOTMAT |

General description |

Detailed description |

Results Presentation

Results Presentation

| Phase I (29.11.2013-17.12.2013)

The first phase of the project "Study on advanced composite materials, coating systems, process definition and preliminary requirements", is presenting a preliminary study regarding advanced composite materials, metallic coating systems for composite space structures and specify the processes and preliminary requirements for their development. In the first phase, the following activities were accomplished: Activity I.1 "Study of advanced composite materials, coating techniques and processes and related technologies", also, Activity I.2 "Defining the preliminary requirements, surface coating systems". In Activity I.1, a bibliographic study was conducted along with an analysis of different configurations and models with respect to coating systems for composite material structures used in space and related technologies. This study targeted the latest descoveries for the materials used in the space applications and it has focused on setting the performances of these studies related to metallic coatings, advanced composite material structures and "packaging space structure" structural configurations regarding their resistance to critical conditions of low earth orbital space (LEO). This study targeted the latest descoveries for the materials used in the space applications and it has focused on setting the performances of these studies related to metallic coatings, advanced composite material structures and "packaging space structure" structural configurations regarding their resistance to critical conditions of low earth orbital space (LEO). Within Activity I.2, an assessemnet of critical functioning of space structures on low earth orbit (LEO) space environement was done. Starting from this a set of preliminary requirements was defined: for composite material space structures integrating special metallic surface coatings, developed during the project. Within the Project Management, the following activities were performed: Activity 0.1 Activity reports and conclusions regarding proposed objectives; Activity 0.2 Periodically meetings of the project team; Activity 0.4 Dissemination.

Results scheduled and accomplished Phase I

A study emphasizing current research activity at international level regarding advanced composite materials, coating systems, processes and technologies associated was performed. A set of preliminary requirements at which the composite space structure integrating surface metallic coatings must answer, was established. According to the working schedule within the project management, a first reunion was organized "Kick of Meeting" (Nr.1/02 December 2013) for the ADCOTMAT project and the project web page structure was established. The phase I report was prepared and delivered to contracting authority ROSA.

|

| Phase no II - STAR ctr.81/2013

Phase II title : " Materials selection and experimentation "

Implementation period : 18/12/2013-31/12/2014

Phase no II Tasks:

• II.1 Specific requirements definiton

• II.2 Materials Selection and of related specific processes/technologies - Experimental configurations

• II.3 Studies regarding ESA standards and materials, regulations, qualification tests of space structures

• Management and dissemination

Results:

- Specific requirements related to the critical operating conditions in space for the developed (mechanical) structures. The set of requirements was defined based on ESA (ECSS) standards, pointing out the "On-ground Environment" conditions (on Earth, before launch), "Lauch Environment" (during launch), "Space Environment" (in space, on-orbit) which must be taken into consideration when a space subsystem structure of a satellite is designed and manufactured.

- Selected materials used to manufacture the space subsystem structure of a satellite (substrate and surface coatings), indicating the specific processes/technologies for manufacturing of the substrate as well as for surface coatings, technical parameters and experimental options. Material structural configurations presented for the substrate aimed achieving performances as: strength, stiffness and mechanical performances required during launching stage and good resistance for LEO environment (Low Earth Orbit, <1000 km altitude), high vacuum (~10¯⁶Torr), according to ECSS-Q-ST-70-02C (15.11.2008), extreme temperature resistance (depending on material orientation toward the sun, thermal cycles [-100°C; +100°C]), ionizing radiation resistivity (∝,ß, X rays, but in general UV and γ). The defined configurations are based on advanced composite materials CFRP (carbon fiber reinforced polymeric thermoset material). Surface coating configuration systems (metallic, nonmetallic, oxide, etc.) aimed to ensure the structure's strength and durability of the strcture during the entire mission in LEO environment (Low Earth Orbit, < 1000 km altitude), impact (micrometeorites, "space debris" particles), abrasion (exposure, hyperthemal collisions with atomic species, ex. oxygen atoms-AO), radiation shielding.

- Two studies on ESA standards and materials, norms, space structure certification tests

- Technical meeteing (nr.2/25.04.2014 and Nr.3/08.08.2014), results dissemination (presenting the results at Romanian Space Week Conference, 12-16 May 2014, Bucharest), updating the ADCOTMAT project webpage (http://www.comoti.ro/ro/Proiect_ADCOTMAT.htm?pag=3) and reporting the results (Phase report towards contracting authority)

Conclusions :

The Phase II "Materials selection and experimentation" objectives were achieved. During this phase the specific requirements for the space structure integrating advanced composite materials structural design including performant coating systems were defined. Defining a clear set of requirements, that composite materials space structure integrating performant coating systems shall meet, is the project basis, and understanding the exact events and parameters that the coated structure is subjected ensures the proper development of the project and achieving the results at pre-established technical level. The materials that will be studied in the third phase of the project were selected along with the associated processes and technologies for the mechanical structure and for the coating system developement. Two research studies regarding ESA standards and materials, regulations, qualification tests of space structures were performed. During Management and dissemination activity, two technical meeting were organized, the project website was updated with the recent results (Phase no 1) that were disseminated whitin Romanian Space Week 12-16 of may 2014. The phase report was draw up and submitted to the contracting authority.

|

| Phase no. III Ctr. 81 ROSA/2013 - ADCOTMAT -

Phase III title: "Development and assessment of design solutions for the space packaging structure"

Implementation period: 31.12.2014 - 11.12.2015

Phase no. III Tasks:

• III.1 CAD model(s) and structural materials design development

• III.2 FEM simulations on structural materials designs of the composite coated packaging space structure

• III.3 Selection of the optimum test configurations: materials, structure design and process parameters

• III.4 Design of the mold for the composite coated packaging space structure

Results:

Task III.1

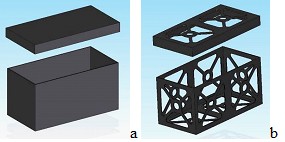

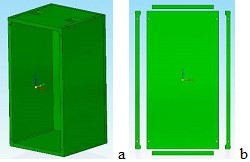

The packaging structure that will be developed during the next phase of the project is the mechanical structure of a nanosatellite model 2U CubeSat. The CubeSat concept was developed in 1999 as a collaboration between California Polytechnic State University (Cal Poly) and Stanford University's Space Systems Development Laboratory. The CubeSat is a small satellite, equipment with reduced weight and smaller size than a conventional satellite and in the last years it was widely used for all type of missions. CAD designs for the CubeSat were modelled with SolidEdge ST4 software. The experimental model will be manufactured as a solid model (Figure 1a) and after the manufacturing process it will be mechanical processed using a pattern to get the skeleton version (Figure 1b).

Figure 1 CAD model of the 2U CubeSat structure. a) Optimum solid model CubeSat; b) Optimum skeleton model CubeSat - final structure

To manufacture the substrate two polymeric composite material precursors - prepregs were chosen:

- EP 127-C20-45 T2 (thermoset matrix: epoxy-cyanate ester blend, reinforcement: 60% carbon fiber)

- M49/42%/ 200 T2X2/ CHS-3K (thermoset matrix: epoxy resin, reinforcement: 58% carbon fiber).

Different type of coatings were analyzed: metallic materials (Zn, Al, Cu), intermetallic compounds (Ni-Al: 95-5) and functionally graded materials - FGMs (Zn/Ni-Al: 95-5, Zn/Ni-Al: 95-5/Cu). The FGM coatings are characterized by a gradual variation in volume, chemical composition and structure, which leads to a gradient of properties in the material so multifunctional surface coatings can be obtained.

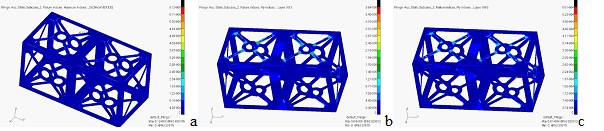

Task III.2

The numerical simulations (static and modal analysis) were realized using NASTRAN and ANSYS programs and were made on two material designs. For the FEA analysis were used the particularities of Vega launcher in terms of maximum loads and accelerations. The first design - Design 1 - was a CubeSat structure with the substrate made of 8 plies of M49/42%/200T2X2/CHS-3K with a symmetrical integrated aluminum foil (0,009 mm thick) and on top of the substrate was a FGM metallic coating with a total thickness of 100 μm, coating composed of one Zn layer (50 μm), and one NiAl 95:5 layer (50 μm). The second design - Design 2 - was a CubeSat structure made by 8 plies of EP 127-C20-45 T2 which integrates a Ta foil (0,08 mm thick) and Cu (50 μm) metallic coating on top of the substrate.

Figure 2 FEM simulations on 2U CubeSat - Design 1

Figure 3 FEM simulations on 2U CubeSat - Design 2

As a preliminary conclusion, the 2U CubeSat structures made of CFRP which integrate metallic coatings showed a good mechanical resistance under static loads, loads taken from the User Manual of Vega launcher. Regarding the modal analysis, the natural vibration frequencies of the CubeSat are in the imposed limits, outside of the critical range of 1-125 Hz.

Task III.3

During Task III.3, several materials designs for the substrate were proposed using the two advanced composite precursors, integrating powders and metallic foils with high Z, additions used to increase the protection of the structure against gamma radiation (Low Z-High Z- Low Z concept). The first material design configuration proposed to be manufactured and tested was a laminate made of 8 prepreg plies which integrates symmetrically an aluminum foil (0,009 mm thick, Z=13). The same configuration with 8 plies was proposed, this time integrating a tantalum foil (0,08 mm thick, Z=73). Other proposed material design configurations were integrating powders: configurations composed of 8 prepreg plies with metallic powders after every 2 plies. The selected powders were: Al-Si alloy powder (88%Al, 12% Si), Ni powder (purity >90%, Z=28), Mo powder (particle diameter 45μm, Z=43). For the manufacturing process of the composite samples, autoclave technology was chosen.

Two coating techniques were evaluated: thermal spray coating and magnetron sputtering. The materials selected to coat the composite substrate were: aluminum, zinc, copper, FGM coatings: Zn/ Ni-Al: 95-5 and Zn/ Ni-Al: 95-5/Cu.

Task III.4

The optimum CAD model was used as input for the mold design. Three types of molds were proposed along with different materials suitable for the manufacturing process:

- wood - material easy to machine, can be used at temperatures exceeding 100oC, chemical decomposition of the wood starting at temperatures over 105oC, the flashpoint of the wood being between 200-275oC.

Figura 4 CAD model of the wood mold

- Necuron 702 - board made of epoxy resin suitable to manufacture mold used for polymeric composite structures with cure temperatures in the temperature range 130-140oC, pot fi folosite pentru realizarea matritelor pentru structuri din compozite polimerice armate cu fibre de carbon;

Figure 5 CAD model of Necuron 702 mold

- steel - to manufacture this type of mold multiple steel sheets are required; the mold is designed to allow the manufacturing of multiple polymeric composite structures in the same time.

Figure 6 CAD model of the metallic mold: a) CubeSat cover; b) CubeSat body

Conclusions:

The goals of Phase III "Development and assessment of design solutions for the space packaging structure" have been met. During this phase: was set the structure that will be manufactured during the next phase of the project: a 2U CubeSat; the CubeSat CAD models were designed and the optimum design was chosen. Aspects regarding the material structural designs were defined based on the results of the numerical simulation (finite element analysis). The material configurations proposed to manufacture and testing were evaluated, a preliminary test campaign was made at laboratory level to characterize the substrate materials and the coating materials (microstructural analysis, thermogravimetric analysis and dynamic differential calorimetry - Tg-DSC), determination of the thermal conductivity, gamma irradiation of the samples, expansion coefficient of the samples, scratch tests). During this phase different designs and materials were proposed for the mold of the 2U CubeSat structure manufactured form advanced composite materials. In the Management and Dissemination task a technical meeting was held, the web page of the project was updated with the results of the Phase no. II and the preliminary results of the project were disseminated within Romanian Space Week 27-29 May 2015.

|

| Phase no. IV Ctr. 81/2013 - ADCOTMAT -

Phase no. IV title: "Achievement of the space packaging space structure experimental models. Validation through test campaign"

Implementation period: 17.12.2015 - 29.09.2015

Phase no. IV Tasks:

• IV.1 Mould manufacturing for the advanced composite lightweight coated space packaging space structure

• IV.2 Manufacturing of advanced composite lightweight coated space packaging space structure: experimental model(s)

• IV.3 Characterization and evaluation: tests

Results:

Task IV.1

During Task IV.1 two moulds were manufactured and used in the next task (IV.2) in order to manufacture the lightweight space structure. For the mould manufacturing, the following aspects were assessed:

• final design of the lightweight space structure;

• CAD design of the moulds;

• material for the lightweight space structures;

• material selection for the moulds.

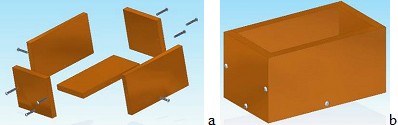

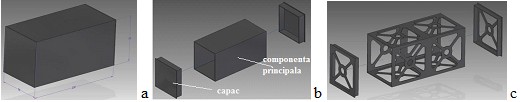

The final design of the lightweight space structures

Initially (during Phase no. III), a CubeSat structure with only one detachable component (one cap) was chosen to be manufactured, but after further analysis it was concluded that the space structure will have two detachable components (caps). The body of the CubeSat will be fixed and manufactured from continuous plies of composite material, ensuring a superior mechanical resistance in that area.

Figure 1 CAD model of the CubeSat - final design. A) CAD model of the solid version of the CubeSat; b) CubeSat's components; c) CAD model of the skeleton version of the CubeSat

Mould design

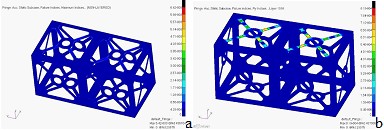

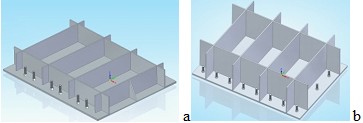

Two moulds were designed for the manufacturing process of the CubeSat: one mould used for the caps and one mould used to manufacture the body. The moulds were designed to allow the manufacturing of two components simultaneously (Figure 2).

Figure 2 Moulds designed to manufacture the CubeSat. a) CAD model of the double mould used for the CubeSat's body; b) CAD model of the mould used for the CubeSat's caps

The material for the manufacturing process of the lightweight space structures

The aerospace materials have to be high performance materials providing: a low outgassing rate, high resistance to microcracking, dimensional stability (a low thermal expansion coefficient) during exposure to high/low temperatures (thermal cycling), gamma radiation resistance, atom flux attack resistance, proton and electron shielding, UV and VUV shielding. The material selected for the manufacturing process of the final structure was EP 127-C20-45 T2. This material was selected due to high resistance when operating at temperatures both negative and positive (-55oC...+185oC) and due to the research studies about the resistance of polymeric composites in space, the cyanate ester resins being used to manufacture structural components for the aerospace field (satellite's components, antennas, reflectors, optical elements, high precision detectors, solar panel's substrates etc.). The structural material design integrates the concept Low Z - High Z - Low Z, this concept has an important role in increasing the structure shielding against cosmic rays formed especially from protons, electrons, heavy ions and alpha particles.

The material for the mould manufacturing

The material chosen for the mould manufacturing process was Necuron 702. This material is distributed as boards, manufactured from epoxy resin. Necuron is suitable for the manufacturing of moulds to cure structures made by polymeric composites reinforced with fibers.

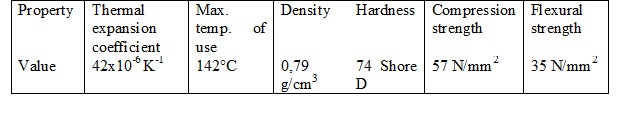

Table 1 Properties of Necuron 702

The manufacturing process of the moulds

The mould components were cut and milled from a Necuron 702 board. The active surfaces of the moulds had to be flat surfaces with a reduced roughness to avoid the adhesion between the polymeric composite and the surface of the mould and to obtain even surfaces of the structure. To reduce the roughness of the mould, the surfaces were polished with sand paper and then was applied a gelcoat - Necuron V7.

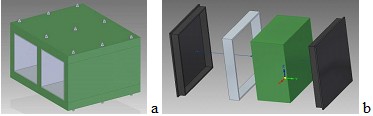

Task IV.2

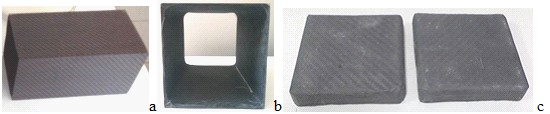

The autoclave technology was chosen to manufacture the lightweight space structure. In Figure 3 can be observed the components of the space structure.

Figure 3 The CubeSat's components. a,b) the CubeSat's body; c) the CubeSat's caps

The CubeSat face's design (skeleton version) was realized with a water jet cutting machine.

Figure 4 a) the CubeSat's body during the cutting process; b) the CubeSat's body after the cutting process; c) the CubeSat's caps

The skeleton version of all CubeSat's components were sandblasted and coated with Zn, Babbitt and Zn/Monel (Figure 5). After the coating process the CubeSats were assembled with rivets A3 (DIN 7337) ø=3.2 mm l=10 mm (Figure 6).

Figure 5 a) CubeSat's body after the sandblasting; b) CubeSat's body during the coating process; c) CubeSat's body after the coating process

Figure 6 Assembled CubeSsats

Task IV.3

During this task two types of tests were realized:

• Vibration tests;

• Proton irradiation tests;

• Electron irradiation tests.

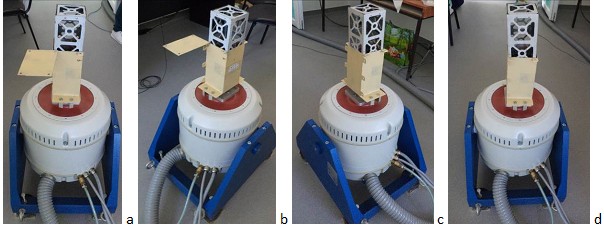

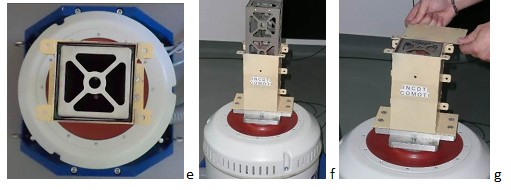

Vibration tests

The vibration tests were focused on reproducing the dynamic environment during the launch of the satellite. The CubeSat structures were subjected to various testing profiles to observe if they meet the qualification requirements for mechanical space structures. The vibration tests were performed according to the QB50 qualification requirements. A shaker was used to perform the tests. The structures were validated and their first vibration mode overcomes 100 Hz.

Figure 7 Structure's fitting on vibration device

Proton irradiation tests

Irradiation simulations were performed before the testing, using the SRIM (Stopping and Range of Ions in Matter) programme which calculates the interaction of ions with matter. As input data were used the structural material designs used to manufacture the three CubeSats along with CFRP references and aluminum reference. The beam's energy was considered to be 15MeV and 1,45 g/cm3 the density of the CFRP. It was observed that the beam can't pass through all three proposed structural material designs at an energy of 15 MeV, but the best performance was observed in case of CFRP sample coated with Zn/Monel integrating Ta foil. The irradiation tests with proton beam were realised at Horia Hulubei National Institute for R&D in Physics and Nuclear Engineering, using the accelerometer HVE FN Tandem Van de Graaff de 9MV. Samples were used as target for the proton beam; they were introduced in vacuum chamber inside the accelerometer (3*10-6 bar). Behind the samples, after the high energy magnet, a Faraday cup was placed to register the electrical current that passes through the sample. The irradiation time for a sample was between 15÷30 s, and the beam's energy 15,8 MeV. It was observed that the CFRP samples integrating LowZ - High Z - Low Z concept and metallic coating don't allow the proton beam to penetrate the laminates, therefor no electric current was detected by the Faraday cup and the SRIM simulation results were accurate.

Electron irradiation tests

The purpose of the test was to determine the samples ionized radiation shielding capability (electron beam with average energy of 6 MeV). The irradiation tests were performed at the National Institute for Laser, Plasma and Radiation Physics, at the Electron Accelerators Laboratory, using the electron linear accelerator ALID-7. It was observed that all composite material samples reduce the electron beam (shielding percentage between 6,7÷58,7%). The electron shielding capacity of the metallic coating and of the tantalum foil was determined, ~200 μm of Zn shields 0,245 MeV, ~200 μm Babbitt shields 0,253 MeV, the Zn/ Monel coating (~100 μm / ~100 μm) shields 0,274 MeV and the tantalum foil shields 0,240 MeV.

Conclusions:

The goals of Phase IV were fully achieved. The moulds used to manufacture the lightweight space structure - CubeSat - were realised starting from the final design of the CubeSat, from the selected materials for the structure and for the moulds and from CAD designs of the moulds. Three CubeSat structures were manufactured using CFRP and integrating the Low Z-High Z-Low Z concept (tantalum foil) and metallic coating systems (Zn coating, Babbitt coating and Zn/Monel coating). All three coated Cubesat structures were submitted to vibration testing. The structures were validated and the first vibration mode was higher than 100 Hz. Proton and electron irradiation tests (charged particles found in space) were completed, and it was observed that the proposed material designs ensures ionized radiation shielding.

During Management and Dissemination activity, a technical reunion was organized, the web-site of the project was updated, the preliminary results of Phase IV were disseminated within Romanian Space Week 2016 organized by ROSA and a scientific paper was published within Revista de Materiale Plastice (Voicu. R. - "CFRP Composite behaviour under extreme environmental exposure", Revista de Materiale Plastice, Vol. 53, No. 3, 2016)

|

|

General description |

Detailed description |

Results Presentation

|

|

| |

|

|

|