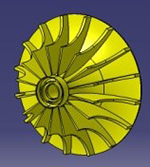

ManuCFBlade - Light weight carbon fiber compressor impeller/blade manufacturing study

GENERAL DESCRIPTION

MANUNET PROGRAM call 2012

contract (by Romanian Authority) MNT 7077

Coordinator:

COMOTI Romanian research and Development Institue for Gas-Turbines, Romania

Partner 2:

L'Uredera, Fundacion para el Desarrollo Tecnologico y Social, Spain

Partner 3:

Grado Zero Espace srl, Italy

Partner 4:

University Dunarea de Jos of Galati, Romania

Partner 5:

SC STRAERO SA, Romania

Summary:

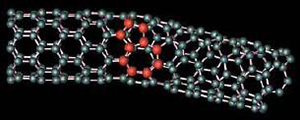

The goal of ManuCFBlade project is to achieve Technology Readiness Level 4 and some steps towards TRL 5 and 6 for using light weight composite materials like carbon fiber for the impeller of aerodynamic compressors, taking the aerodynamic compressor beyond the state-of-the-art. The target for ManuCFBlade is the rotating assembly of such compressors since they represent the biggest challenge in weight reduction. The proposed research will result in reduction of the total weight of the rotary assembly and in better performances related to fuel consumption and pollutant emission reduction for energy machines having aerodynamic compressors.

The list of specific objectives for ManuCFBlade is as follows:

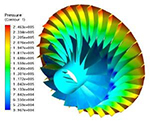

A. aeroelastic design studies on complex geometry of aerodynamic compressor impellers; aerodynamic and mechanical coupled studies in order to define the general demands and special demands from the point of view of manufacturing material (computer tools like Computer Aided Design, Computational Fluid Dynamics and Finite Element Analysis will be employed to give accurate and extensive results of fluid and elastic fields as well as of fluid-elastic fields coupling to simulate real working conditions); material design with respect to the required characteristics is an integrated part of this objective since for composite material separation cannot exists due to complex behavior in real functional conditions; the coupled studies for compressor configuration will give indications to its aerodynamic, mechanic and aeroelastic answers and will underlie the general and special requirements from material manufacturing point of view;

B. mechanical balancing study; rotor systems for energy machines like gas turbines which spin at high speed (10.000 rpm to 60.000 rpm) must be carefully balanced; for composite rotors we must define the technological constrains to be observed when building such systems (although balancing is well known and even standardized for rotary parts, when speaking about very light components the problem may be difficult and will be studied with respect to composite materials manufacturing processes);

C. manufacturing of composite components to be tested and impeller/blade demonstrator; composite probes and composite impeller/blades for aerodynamic compressors will be manufactured and; the proposed technology is the autoclave technology which is rather old but its application for compressor blades and impellers is still a challenge for manufacturers; this is the main part of the project but it cannot be conceived without the other steps since for composites the manufacturing process is very strong related to the design one;

D. experimental data interpretation (parts checking for conformity with the proposed design); the real mechanical answer of the obtained probes will be checked and analyzed with respect to the initial design requirements by performing different physical tests; the tests will be designed in order to simulate the real functioning conditions of such complex parts;

E. evaluation/validation and economic study of the proposed technology (validation and economic study to assess the possibility for series production and market analysis.

Objective A

Aeroelastic design studies |

CAD - CFD/FEM aeroelastic analysis |

Objective B

Mechanical balancing studies |

balancing of impeller/blade for centrifugal compressors |

Objective C

Manufacturing of components |

material testing

probes and composite blades |

Objective D

Experimental data interpretation |

3D measurement on composite blade |

Objective E

Economic study |  |

Project duration (by Romanian Authority): 20 months

Starting date (by Romanian Authority): 21.06.2013

Total project costs: 915.091 EURO

Contact person: dr .ing. Valeriu VILAG, e-mail: valeriu.vilag@comoti.ro