|

|

|

| |

|

Development of equipment for space industry |

|

|

COMOTI Space Programs Capabilities

3D Modelling

Optimization and CFD analysis

Finite Element Analysis (thermal calculus and stress and vibrations)

Assemblies and components manufacturing using metallic and composite materials.

Space components made of composite materials developed in the frame of the STAR national program.

Through the Research and Development for Space Equipment Department, INCDT COMOTI aims to:

- Ensure the coordination of the space equipment and services projects;

- Identify new opportunities to engage in space industry;

- Ensures the visibility of COMOTI space services during specialized events and keeps contact with potential collaborators.

COMOTI services for space industry:

- Design of components and devices (Catia, Solidedge, Autocad, Unigraphics);

- Resistance calculation and vibrations (Patran, Nastran, others);

- Fluid dynamic calculation and analysis with CFX;

- Manufacturing;

- Assembling;

- Research and development for dedicated solutions.

COMOTI facilities for space industry:

- Manufacturing machines for mechanical processing;

- Test benches for noise and vibration (Shaker TiraVib ..);

COMOTI projects in the space domain/industry:

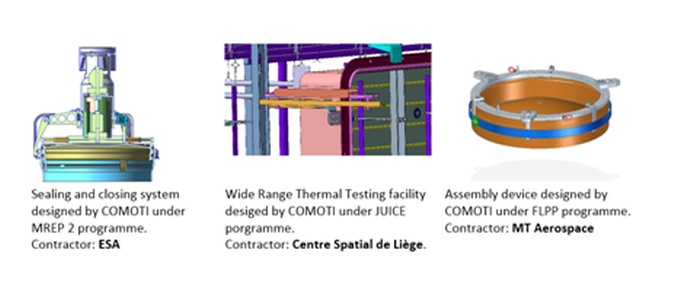

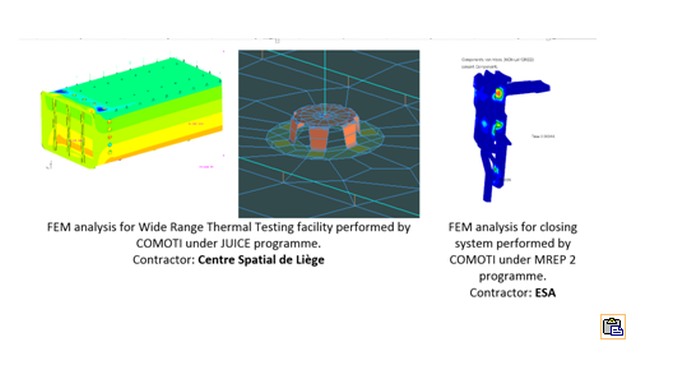

| JUICE-WRTF

In this project COMOTI aims to design, calculate and manufacture the two enclosures (the “small” version shall accommodate a useful internal volume of =1.8m x 1.6 m x 2.0 m (LxWxH) and the “large” version shall accommodate a useful internal volume of =5m x 2m x 3.5m (LxWxH)) made of stainless steel sheet and profiles..

|

| SEALPHO

In this project COMOTI's task was to analyze two existing concepts for the sealing system of the Earth Return Capsule which will bring 100g of sampled material from Phobos surface (one of Mars’s moons), to develop, design and optimize a sealing system capable to fulfill all the requirements imposed by ESA and to make a preliminary test and development plan necessary in the second phase of the project. |

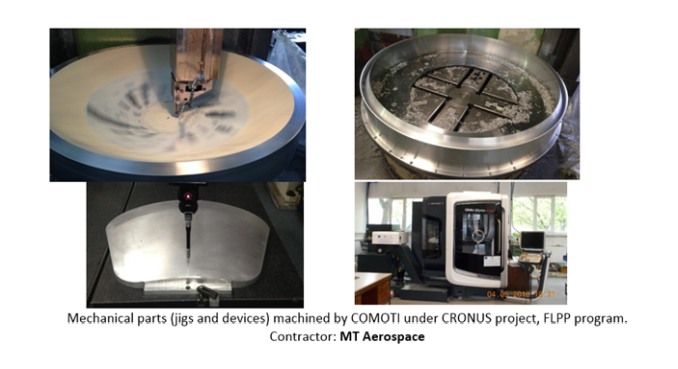

| CRONUS

In the frame of this project, COMOTI successfully designed and manufactured the devices necessary for vacuum clamping, thermoforming, edge milling and assembling, but also components which are part of the tank demonstrator - an Y-ring, upper and lower man hole cover and flanges. |

| PROBA-3

COMOTI's role in this project is to design and manufacture Mechanical Ground Support Equipment (MGSE). |

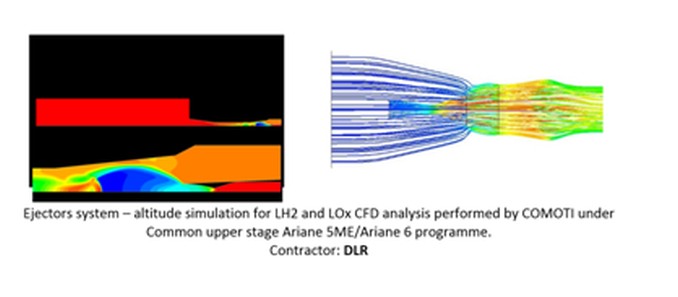

| Test bench P5.2 for U/S

In the frame of this project, COMOTI conducted a study in which, according to the requirements imposed by DLR, designed and manufactured the conceptual model, performed FEM calculus and also developed an P&ID (automation scheme) for the two hydrogen and oxygen ejectors. |

| GREENTH

The project focuses on the experimental demonstration of H2/O2 pulsed technology, in relevant environment, with application as attitude control thruster for small-scale satellites/CubeSats. |

| PEMSAPU

In the PEMSAPU project the experimental model for an APU unit based on PEM fuel cells, dedicated for space applications, was developed. The unit had to be capable to operate in a closed environment, characterized by low gravity, without modifying the external humidification of the reactants (hydrogen and oxygen). |

| ADCOSSPA

Advanced Composite Structures for Space Applications |

| DevPump

Advanced Strategic Planning for the Development of a turbopump system used to power a rocket engine using liquid fuel. |

| ADCOTMAT

Advanced metallic coating systems for composite structures destined for space applications |

|

|

|

|

|

|

© 2021 COMOTI - Romanian Research and Development Institute for Gas Turbines. All rights reserved.

|

| |